Sunflower oil is considered to be one of the most stable oils for cooking, with high content of the essential vitamin E and low content of saturated fat. It is also known for having a clean taste and low levels of trans fat.

Batch-type sunflower oil refining equipment with capacities ranging from 1 to 20 tons per day (TPD) is a cost-effective and flexible solution ideal for small to medium-scale producers. This system effectively transforms crude sunflower oil, which contains impurities like free fatty acids (FFAs), gums, and pigments, into high-quality, stable, and odorless refined edible oil through essential processes of degumming, neutralization, bleaching, and deodorization. Its compact design, relatively low initial investment, and easy operation make it a popular choice for new businesses entering the edible oil market.

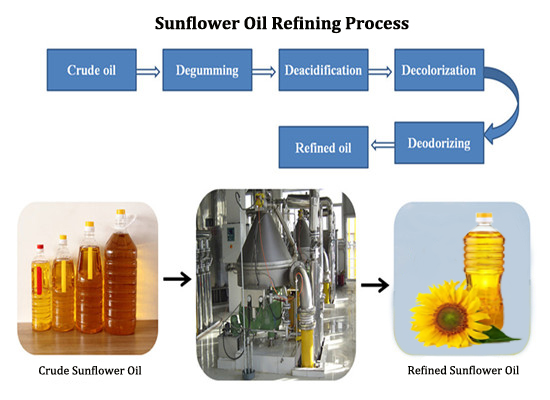

The batch-type refining process for sunflower oil (1–20 TPD) typically involves five main stages to transform crude oil into high-quality edible oil.

1. Degumming

Purpose: To remove phospholipids (gums) that cause oil to emulsify and darken when heated.

Process: Crude oil is heated to approximately 50–80°C. Hot water or food-grade phosphoric acid (0.1–1%) is added with fast stirring. The gums absorb water, become oil-insoluble, and settle for separation.

2. Neutralization (Deacidification)

Purpose: To remove Free Fatty Acids (FFA) that affect oil stability and taste.

Process: An alkaline solution (typically caustic soda/NaOH) is added to the degummed oil. It reacts with FFAs to form soapstock, which settles at the bottom and is discharged. The oil is then washed with hot water 2–3 times to remove residual soap.

3. Bleaching (Decolorization)

Purpose: To remove pigments (like carotene and chlorophyll), trace metals, and residual impurities.

Process: Neutralized oil is heated under a vacuum (typically 95–108°C) and mixed with bleaching earth (1.5–5% of oil weight). The mixture is stirred for about 30 minutes before being passed through a filter press to remove the spent clay and pigments.

4. Dewaxing (Winterization)

Purpose: Sunflower oil contains 0.06–0.2% wax, which makes it cloudy at low temperatures.

Process: The oil is slowly cooled to 4–10°C for up to 48 hours to allow waxes to crystallize. These crystals are then filtered out, ensuring the oil remains clear even when refrigerated.

5. Deodorization

Purpose: To remove volatile compounds, odors, and any remaining FFAs.

Process: The oil is heated to high temperatures (230–260°C) under a high vacuum. Direct steam is injected to strip away odor-causing compounds. The refined oil is then cooled and undergoes a final safety filtration before packaging.

Refining pot (for degumming and deacidification)

Decolorization pot (for pigment removal via adsorbents like activated carbon)

Deodorization pot (for odor removal under high vacuum and high temperature)

Filtration units (to separate adsorbents and sludge)

Vacuum system and steam generator (for process support)

Choosing between batch and continuous refining for sunflower oil depends on your target production volume and budget for 2026. Batch refining is the standard choice for capacities under 20 TPD, while continuous refining is preferred for large-scale operations exceeding 30-50 TPD.

Pros:

High Flexibility: Easily switch between different oil types (e.g., sunflower, palm, soybean) without extensive reconfiguration.

Simple Operation: Requires less complex machinery and a smaller physical footprint.

Flexible Scheduling: Production can be paused or adjusted based on daily demand or electricity peak-hour costs.

Cons:

Lower Efficiency: The sequential nature (stopping and starting) leads to longer total processing times per unit.

Higher Energy Consumption: Frequent heating and cooling cycles increase energy waste compared to a steady-state continuous flow.

Labor Intensive: Requires more manual intervention and technical skill from operators to ensure quality.

Inconsistent Quality: Product quality can vary between batches depending on operator performance and raw material changes.

Pros:

High Efficiency & Yield: Maximizes oil output while minimizing losses through automated, uninterrupted processes.

Consistent Quality: Real-time monitoring and automated controls ensure every liter of oil meets exact specifications.

Energy Savings: Minimizes heat loss by maintaining constant operating conditions.

Scalability: Optimized for handling massive volumes with lower per-unit labor and operational costs.

Cons:

Limited Flexibility: Switching oil types requires significant cleaning and system downtime, making it less suitable for variety.

High Complexity: Requires highly skilled technicians for complex maintenance and troubleshooting.

High Risk of Downtime: Even minor malfunctions can halt the entire production line, leading to significant economic losses.